Neoprene Elastomeric Bridge Bearings for Highway & Rail Projects

Introduction

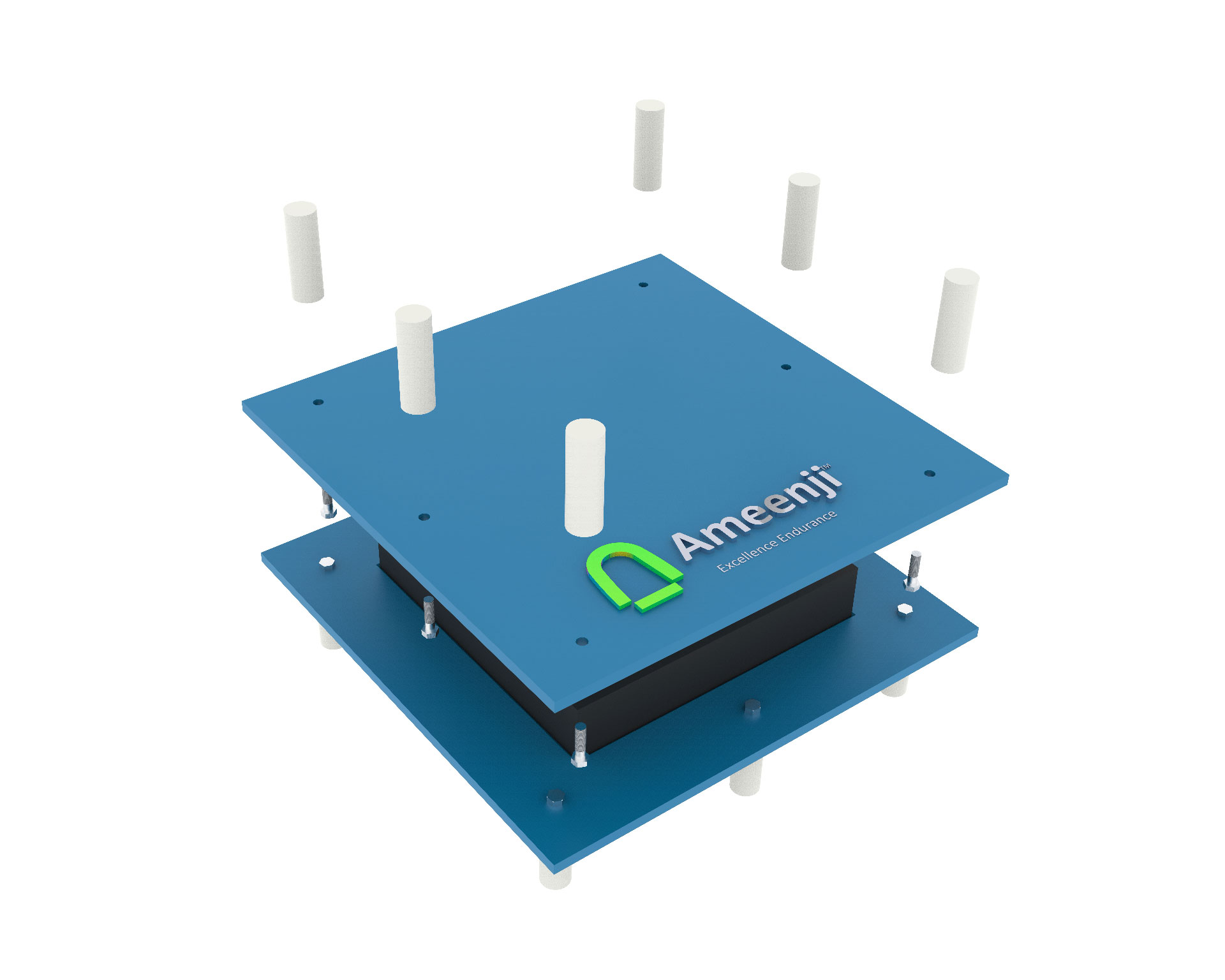

Elastomeric Bridge Bearings

Ameenji Rubber Limited is a leading provider of superior quality elastomeric bridge bearings designed to support bridges and large structures with optimal flexibility, load distribution, and longevity. Our elastomeric bridge bearings are crafted to absorb movements, reduce vibrations, and protect structures from stress and wear caused by dynamic loads, temperature changes, and seismic activity. Ideal for bridges, flyovers, and elevated roads, Ameenji’s elastomeric bridge bearings are engineered for durability, resilience, and smooth structural performance.

Key Features

- Flexibility : Elastomeric materials can deform under load and return to their original shape, which is crucial for accommodating thermal expansion, contraction, and other movements in the bridge structure.

- Durability : These bearings are designed to withstand harsh environmental conditions, including temperature extremes, UV exposure, and chemical exposure, ensuring long-term performance and reliability.

- Low Maintenance : The simplicity of their design and the robustness of the materials used mean that elastomeric bridge bearings typically require minimal maintenance compared to more complex bearing systems.

Functions

- Accommodating Movements : They allow for thermal expansion and contraction, vehicular movements, and other structural shifts without causing damage to the bridge.

- Load Transfer : These bearings transfer vertical and horizontal loads from the bridge superstructure to the substructure, ensuring that the forces are evenly distributed and absorbed.

- Reducing Vibrations : The elastomeric material helps dampen vibrations from traffic and other dynamic forces, contributing to the comfort and safety of bridge users.

- Absorbing Impact: They absorb impacts from traffic and environmental forces, reducing stress on the bridge structure and extending its lifespan.

Advantages

- Versatility : Suitable for various types of bridges, including highway, railway, and pedestrian bridges, and adaptable to different design requirements.

- Cost-Effective : Compared to other types of bridge bearings, elastomeric bridge bearing are relatively low-cost and easy to install, making them a cost-effective solution for many projects.

- Maintenance-Free : With no moving parts and high durability, these bearings typically require little to no maintenance, reducing long-term operational costs.

- Resilience: Their ability to return to their original shape after deformation ensures long-term performance and reliability, even under heavy and fluctuating loads.

Steps for Installing Elastomeric Bridge Bearing

Preparation of Bearing Surface:

- Ensure that the surface on which the bearing will be placed is level, clean, and smooth.

- The bearing seats should be free of debris, dust, and oil to ensure proper distribution of load.

- Check for any discrepancies in the dimensions of the bearing seat or the contact area.

Alignment:

- Correct alignment is critical to prevent uneven load distribution or unwanted rotation of the bearing.

- Place the elastomeric bridge bearing in its exact design position, ensuring proper alignment with the structural elements (e.g., beams, girders).

Placement of Bearings:

- Place the bearing pad between the superstructure (such as beams or girders) and the substructure (like piers or abutments).

- Bearings should be handled with care to avoid damage to the elastomer or steel components.

- Use a lifting mechanism if needed, especially for larger bearings.

Load Transfer:

- Gradually apply the load from the superstructure onto the bearing.

- Avoid any sudden impacts or eccentric loads that could lead to uneven stress on the bearing.

Fixing and Securing (Optional):

- In some cases, the bearings may need to be secured to the substructure using anchor bolts or dowels, especially if designed for seismic or large lateral movements.

- Some bearings are left unanchored to allow more movement, but it depends on the design requirements.

Inspection:

- After installation, inspect the bearing to ensure there are no gaps or misalignments.

- Verify that the elastomeric bridge bearing is in full contact with the surfaces.

- Ensure that there is no excessive deformation or twisting of the bearing under the initial load.

Sealing and Protection (Optional):

- In environments where bearings are exposed to harsh weather, additional sealing or protective layers (like coatings or covers) may be applied to extend the life of the bearing.

- Ensure that drainage or water management systems prevent water accumulation around the bearings.

Regular Maintenance:

- Even after installation, regular inspection and maintenance are necessary to check for wear, damage, or deformation.

- Ensure that the bearings continue to perform their intended functions as designed.

By following these steps, elastomeric bridge bearings can be properly installed to allow the necessary movement and load distribution in the structure while ensuring longevity and performance.

Applications

- Highway Bridges: Accommodating movements due to traffic loads and temperature changes.

- Railway Bridges: Handling dynamic loads from passing trains and structural vibrations.

- Pedestrian Bridges: Providing flexibility and stability for lighter but variable loads.

- Seismic Zones: Offering additional flexibility and energy dissipation during seismic events, protecting the bridge structure.

Frequently Asked Questions

Elastomeric bridge bearings are designed to accommodate movements and rotations in bridge structures caused by thermal expansion, traffic loads, and seismic activity. They ensure smooth load transfer between superstructure and substructure.

Yes, our elastomeric bridge bearings meet IRC:83 (Part II) and MORTH specifications. Each unit undergoes rigorous NABL-accredited testing and quality control.

Absolutely, our elastomeric bridge bearings are manufactured using high-grade neoprene and designed to withstand heavy dynamic loads, ideal for national highways and expressways.

Yes, we offer standard as well as customized dimensions based on bridge span, load calculations, and client requirements.

Under standard maintenance and operating conditions, elastomeric bridge bearings can perform effectively for 20–30 years with proper installation and minimal upkeep.

Yes, we supply detailed installation guides, load test results, and compliance certificates with every order.