POT Bearings

Ameenji Rubber Limited offers top-quality POT-PTFE bearings designed to handle large loads, accommodate structural movements, and withstand environmental factors. Our POT-PTFE bearings are widely used in bridges, flyovers, and other heavy-duty structures due to their excellent load- bearing capacity, durability, and ability to accommodate rotations and translational movements.

Crafted with precision and backed by rigorous quality standards, Ameenji’s POT-PTFE bearings ensure the structural integrity and longevity of essential infrastructure.

Long term serviceability

Inexpensive repair

Heavy load suspensibility and high safety

Key Advantages

1. Outstanding Load-Bearing Capacity

2. Accommodates Multi-Directional Movement and Rotation

3. Low Friction and Smooth Operation

4. Durability in Extreme Conditions

5. Minimal Maintenance Requirements

6. High Safety and Structural Stability

7. Customizable Solutions to Fit Specific Needs

Ameenji Rubber Limited offers customizable POT-PTFE bearings to meet each project’s unique requirements. Our team works with clients to design bearings that align with load, movement, and environmental demands, ensuring the perfect fit for optimal performance and reliability.

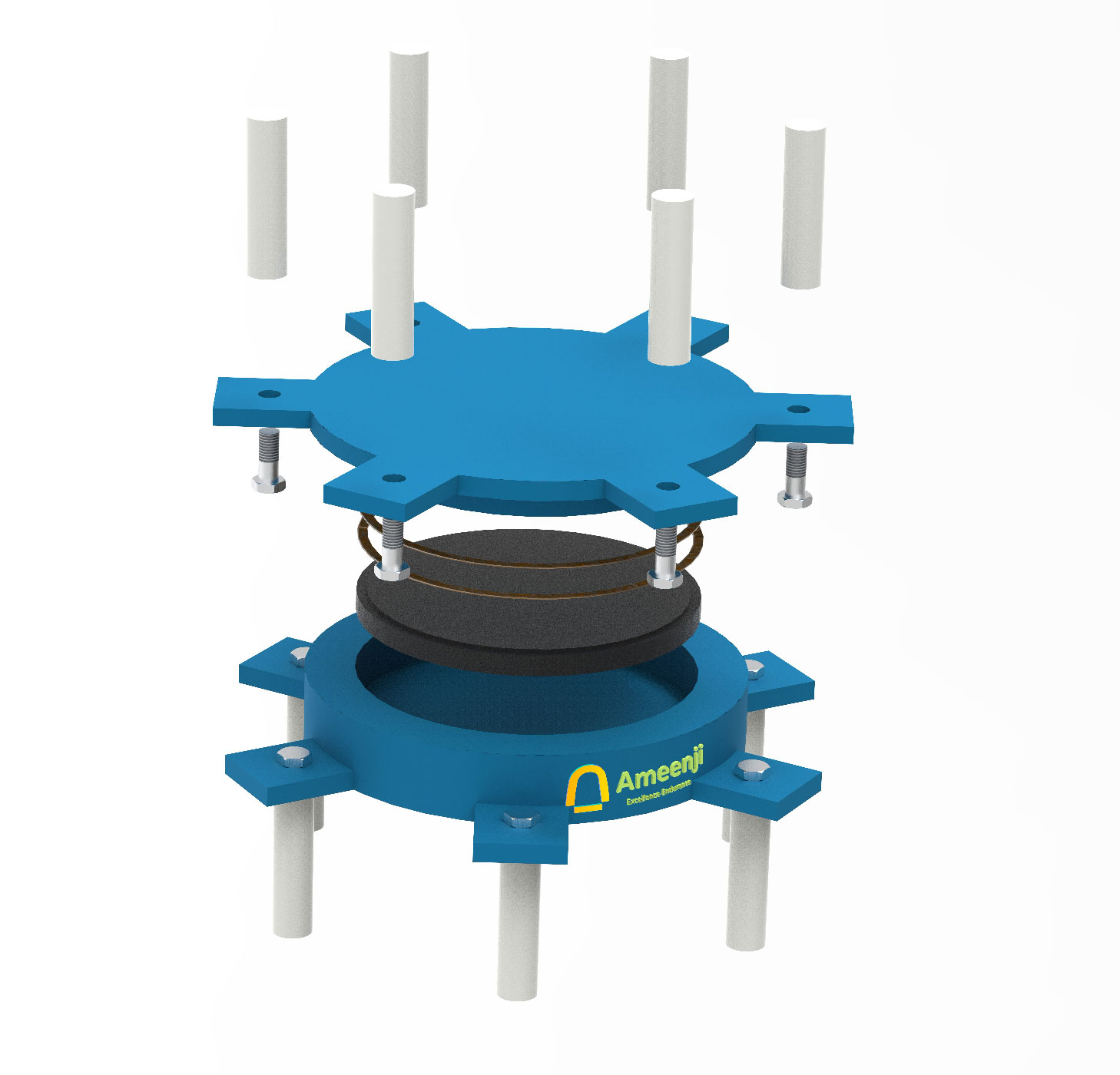

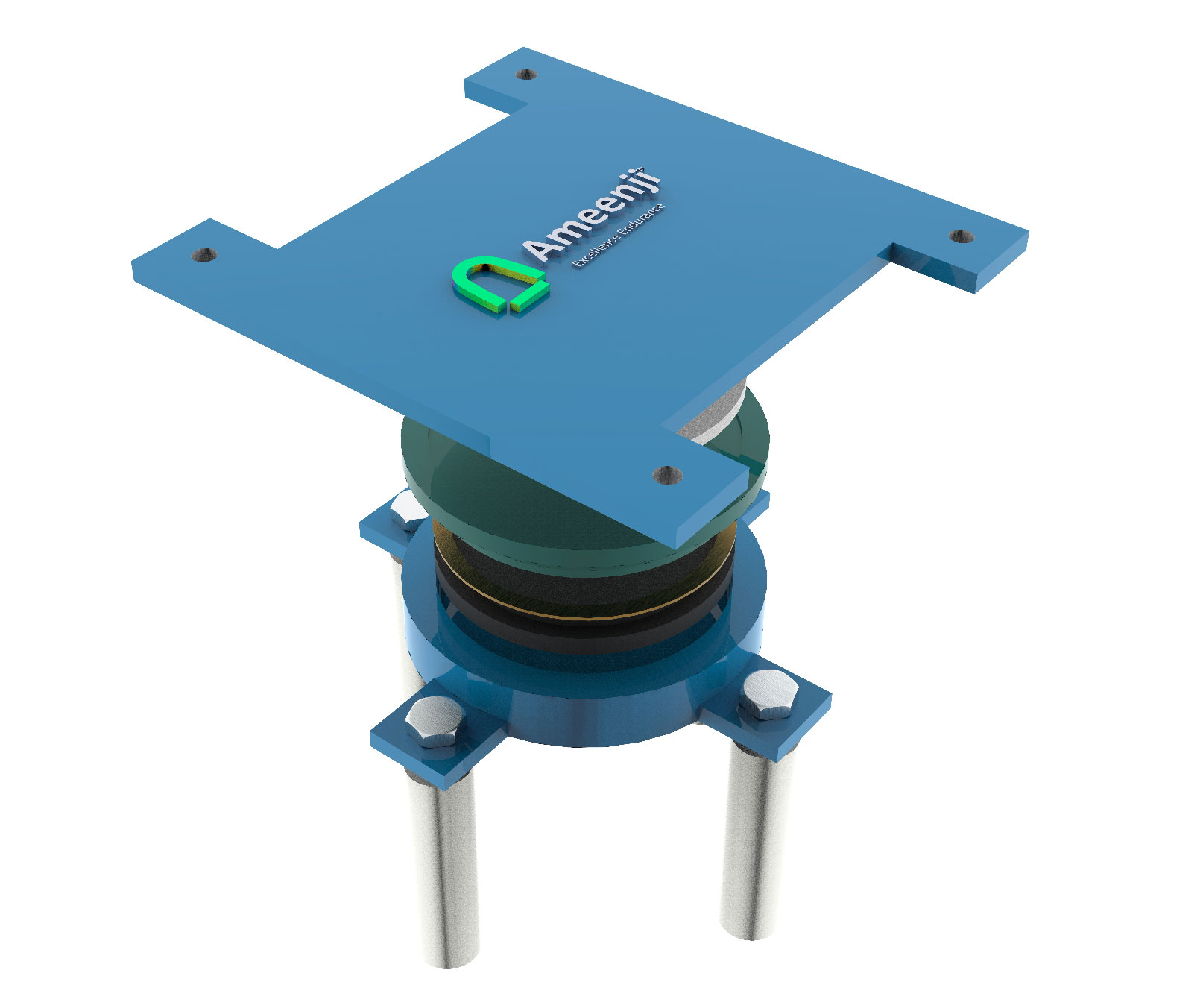

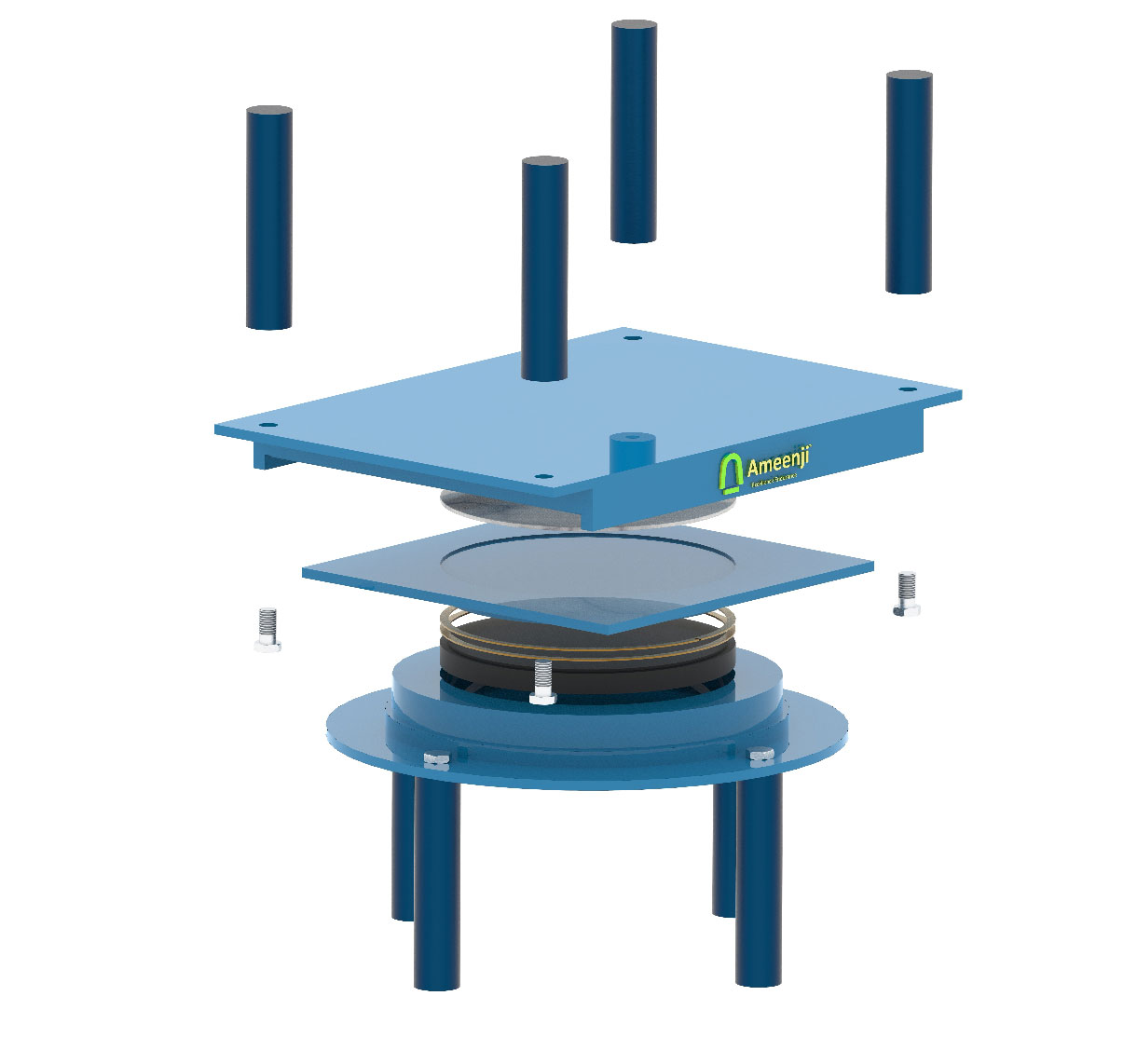

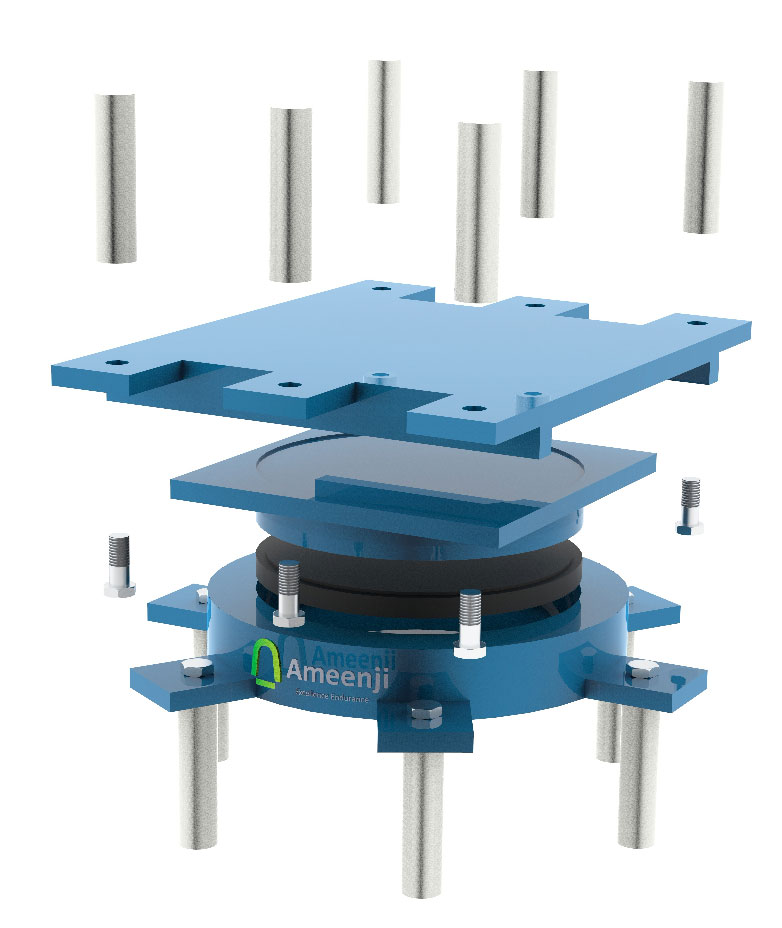

Components of POT Bearings

- Pot: The main body of the bearing, usually made from steel, which contains the elastomeric disc and provides structural support.

- Elastomeric Disc: A confined elastomeric pad placed inside the pot, allowing for rotations by deforming under load while remaining contained within the pot.

- PTFE Disc: A layer of PTFE material that sits atop the elastomeric disc, providing a low-friction surface for sliding movements.

- Stainless Steel Plate : A polished stainless steel plate that slides over the PTFE disc, ensuring smooth translational movement with minimal friction.

- Guide Bars: In guided pot PTFE bearings, guide bars are used to restrict movements to a specific direction, ensuring controlled translations and preventing unwanted lateral movements.