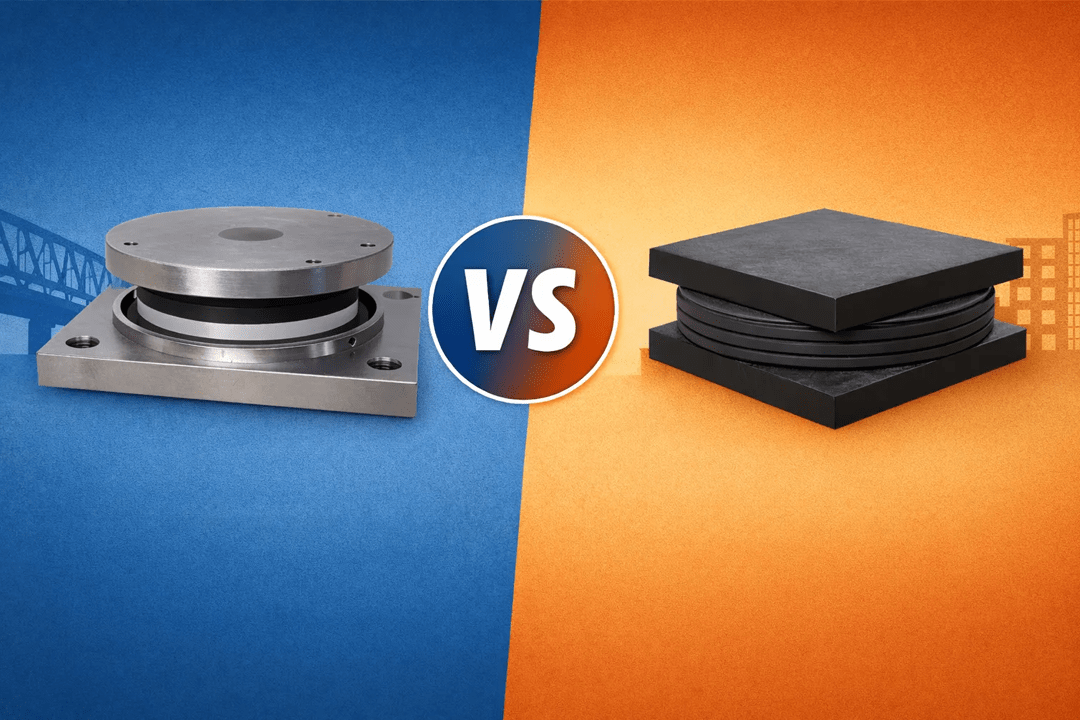

Pot PTFE bearings vs elastomeric bearings is one of the most common comparison points in Indian bridge engineering and procurement decisions. These two systems account for the majority of bridge bearing installations across highways, railways, metros, and large infrastructure projects in India.

Selecting the right bearing system directly impacts structural safety, load performance, construction cost, and long-term serviceability. An incorrect bearing choice can lead to premature distress, excessive maintenance, or movement restriction—making bearing selection a critical design decision rather than a commodity purchase.

Understanding Bridge Bearings and Their Role in Structures

Bridge bearings are structural components placed between the superstructure (deck or girder) and the substructure (pier or abutment). Their primary function is to safely transfer loads while accommodating movements caused by traffic, temperature changes, creep, shrinkage, and seismic effects.

From a design perspective, bearings must:

- Transfer vertical and horizontal loads without overstressing

- Allow controlled rotation and translation

- Protect both superstructure and substructure from induced stresses

Different bearing types exist because bridge configurations vary widely in span length, bearing load capacity, movement demands, and compliance with bridge bearing design standards.

What Are Pot PTFE Bearings

Pot PTFE bearings are mechanical bearings designed to support very high vertical loads while permitting controlled rotation and horizontal movement.

They consist of:

- A steel pot that houses a confined elastomeric disc, which behaves like a fluid under pressure to allow rotation

- A PTFE (Polytetrafluoroethylene) sliding surface, paired with a stainless steel plate, to enable horizontal translation

Due to this configuration, PTFE bridge bearings in India are widely used in long-span bridges, flyovers, and heavily loaded structures. Their robust construction and precision engineering contribute to higher Pot PTFE bearing price in India, but they deliver predictable performance under demanding conditions.

What Are Elastomeric Bearings

Elastomeric bridge bearings are simpler, flexible bearings made from layers of natural or synthetic rubber reinforced with steel laminates.

These bearings manage:

- Vertical loads through compression

- Rotation and translation through elastic deformation of rubber

Because of their simplicity, elastomeric bearings are widely adopted in standard highway bridges, ROBs, and moderate-span structures. Elastomeric bearing applications are best suited where movements are limited and load demands are within defined elastic limits.

Design Differences Between Pot PTFE and Elastomeric Bearings

From a design standpoint, the bridge bearing comparison highlights significant differences:

- Pot PTFE bearings are mechanically complex, using steel, elastomer, and low-friction PTFE interfaces. They separate rotation and translation into distinct mechanisms, making them ideal rotational and translational bearings for complex movement conditions.

- Elastomeric bearings rely entirely on material deformation, combining rotation and translation within a single elastic body.

Pot PTFE systems offer higher precision and load control, while elastomeric bearings prioritize simplicity and ease of installation.

Bearing Load Capacity and Movement Behavior

Bearing load capacity is a key differentiator between these two systems.

- Pot PTFE bearings can support very high vertical loads, often several times higher than elastomeric bearings of comparable size.

- Elastomeric bearings are limited by rubber compression, shear strain, and long-term creep.

In terms of bridge bearing movement types:

- Pot PTFE bearings handle large rotations and long translational movements with minimal resistance.

- Elastomeric bearings perform best under small to moderate movements and predictable load patterns.

For heavy traffic corridors and complex geometry, Pot PTFE bearings typically perform better.

Cost Comparison and Pricing Factors in India

From a commercial standpoint, in India, Pot PTFE bearings generally cost higher than elastomeric bearings due to:

- Precision fabrication

- Use of steel and PTFE materials

- Assembly, testing, and installation complexity

In India, the price of Pot PTFE bearings also reflect inspection, machining tolerances, and quality assurance requirements.

In contrast, elastomeric bearings are more cost-efficient, especially for standard projects, as they:

- Require simpler manufacturing

- Have faster installation

- Incur lower upfront procurement costs

However, initial cost should be weighed against performance demands and lifecycle expectations.

Use Cases in Indian Bridge and Infrastructure Projects

In Indian infrastructure projects:

- PTFE bridge bearings, specifically in India, are preferred for long-span bridges, metro viaducts, flyovers, cable-stayed bridges, and structures with heavy axle loads.

- Elastomeric bearing applications are common in short to medium-span highway bridges, service roads, and rural infrastructure where movement and loads are moderate.

The choice is often dictated by span length, pier height, movement requirements, and approval authority specifications.

Which Bridge Bearing Is Better for Indian Conditions

When asked which bridge bearing is better, the answer is not universal.

A proper bridge bearing comparison shows that:

- Pot PTFE bearings are better for high-load, high-movement, and complex structures

- Elastomeric bearings are better for simpler, cost-sensitive, and standard designs

Indian conditions demand engineering-led selection rather than a one-size-fits-all approach.

Compliance With Indian Bridge Bearing Design Standards

Bearing selection in India must comply with IRC and MORTH bridge bearing design standards. These standards govern:

- Design methodology

- Load combinations

- Testing requirements

- Approval and certification processes

Compliance ensures safety, durability, and acceptance by government authorities for public infrastructure projects.

How Engineers and Contractors Should Choose the Right Bearing

When selecting a bearing system, engineers and contractors should evaluate:

- Required bearing load capacity

- Expected bridge bearing movement types

- Environmental exposure and durability needs

- Maintenance access and lifecycle cost

- Approval requirements and project specifications

A structured evaluation helps balance performance, cost, and long-term reliability.

Choosing Between Pot PTFE and Elastomeric Bearings

In conclusion, Pot PTFE bearings vs elastomeric bearings is a comparison rooted in engineering performance rather than preference. Both systems play a vital role in Indian bridge construction when applied correctly.

Choosing the appropriate bearing improves structural durability, movement control, safety, and cost efficiency, ensuring the bridge performs as intended throughout its design life.

AUTHOR: Mr. Narendera Kumar Singh

ROLE: GM Factories

About The Author

Narendera Kumar Singh is the General Manager of our facility in Kucharam Village, Telangana. He oversees all production activities and manages a large team comprising of production, quality, maintenance etc. With over 30 years of experience, Narendera ji brings his vast experience and knowledge to produce world class products for Ameenji’s clients.