Introduction

As bridges, highways, flyovers, and large civil structures expand and contract due to temperature changes, load variations, and seismic activity, expansion joints become essential for structural safety and long-term performance. Among the most trusted solutions used in modern infrastructure are omega seals and slab expansion joints—each engineered to withstand high movement, vibration, and environmental stress. These systems ensure waterproofing, structural integrity, and seamless load transfer, making them critical for India’s growing network of bridges and expressways. Ameenji Rubber Limited supplies industry-grade, MORTH-compliant expansion joints designed for long-lasting performance in demanding conditions.

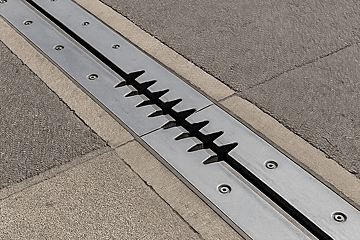

What Are Omega Seals in Bridge Construction?

Omega seals are flexible, rubber-based expansion joint systems shaped like the Greek letter “Ω,” designed to absorb multi-directional movement in large-span structures. They play a vital role in:

- Accommodating high movement ranges caused by temperature shifts, dynamic loads, and seismic forces

- Providing waterproofing protection for bridge decks, tunnels, and retaining walls

- Ensuring long-term durability even in environments with high vibration or continuous traffic loads

- Maintaining structural continuity while allowing safe expansion and contraction

Their adaptability makes omega seals one of the most reliable solutions for bridge expansion joint systems in India.

When and Why Are Omega Seals Used?

Omega seals are deployed in scenarios where structures undergo large and frequent movements, including:

- Long-span bridges and elevated corridors

- Tunnels and metro rail infrastructure

- Seismic-prone regions requiring flexible movement accommodation

- Structures with heavy expansion cycles, such as industrial facilities and rail-over-bridges

Engineers prefer omega seals because they offer excellent leak-proofing, resist chemical exposure, and deliver consistent performance under extreme conditions.

What Are Slab Expansion Joints?

Slab expansion joints are specially designed joints installed between concrete slabs to absorb linear movement and reduce stress on highway or bridge decks. These joints help:

- Prevent cracking due to thermal expansion

- Protect bridge decks from structural fatigue

- Maintain smooth vehicular movement

- Reduce maintenance costs over time

Common use cases include:

- National and state highways

- Flyovers and elevated roads

- Bridge approaches

- Expressway pavements

Slab seal expansion joints in India are widely used because of their balance of load-bearing capacity, waterproofing, and ease of installation.

Key Differences Between Omega Seals and Slab Expansion Joints

| Feature | Omega Seals | Slab Expansion Joints |

|---|---|---|

| Movement Range | Very high (multi-directional) | Moderate (primarily linear/vertical) |

| Design | “Ω” shaped elastomer for large-gap sealing | Elastomeric or strip-seal type for slab-level joints |

| Applications | Long-span bridges, tunnels, seismic zones | Highways, flyovers, general bridge decks |

| Function | Waterproofing + high movement absorption | Load transfer + movement control |

| Installation Scope | Heavy-duty, complex structures | Standard infrastructure projects |

In summary, omega seals are chosen for high-movement, high-stress structures, while slab expansion joints are ideal for roadways and typical bridge decks.

Performance Benefits of Quality Expansion Joints

Both omega seals and slab expansion joints offer critical performance advantages, including:

- Superior load transfer, ensuring safety under heavy vehicular movement

- High durability, resisting fatigue, abrasion, and extreme climate conditions

- Effective waterproofing, preventing moisture infiltration and concrete deterioration

- Movement accommodation, allowing thermal, seismic, and mechanical expansion without damage

- Reduced maintenance needs, improving the life cycle of infrastructure assets

Quality expansion joints directly contribute to longer service life and reduced repair costs in large civil engineering projects.

Ameenji Rubber Limited’s Expertise in Expansion Joints

Ameenji is a trusted name among bridge expansion joint suppliers and omega seal manufacturers in India. Our solutions are engineered to meet the performance demands of national infrastructure.

Why industries choose Ameenji expansion joints:

- NABL-accredited testing ensures consistent quality and compliance

- MORTH-approved designs suitable for national and state-level projects

- Durable elastomer formulations designed for India’s extreme climate and heavy traffic

- Custom manufacturing to match project-specific widths, movements, and installation conditions

- Reliable pan-India supply, including rapid delivery for infrastructure contractors

Whether you need the best expansion joints for bridges, an omega seal supplier in India, or detailed specifications for slab expansion joints, Ameenji delivers performance-built solutions.

Conclusion

Omega seals and slab expansion joints are essential components in modern bridge and highway construction, ensuring movement safety, structural protection, and long-term reliability. With growing infrastructure demands across India, choosing the right expansion joint system is more important than ever.

For tested, MORTH-compliant, and durable solutions, explore Ameenji Omega Seals and Ameenji Slab Expansion Joints tailored to your project requirements.

🔗 Visit Ameenji’s product pages to choose the right expansion joint system for your infrastructure project

AUTHOR: Mr. Mohammad Sirazuddin

ROLE: Assistant General Manager