Introduction

In large-scale infrastructure projects, the choice of bridge bearings plays a critical role in ensuring stability, flexibility, and long-term performance. Rubber bearing types have evolved to address different structural demands—from load transfer to seismic movement control.

Understanding these variations is essential for engineers, project planners, and procurement officers.

In this guide, we’ll explore the major types of rubber bearings used in bridges and buildings, compare their performance, and outline real-world use cases. Whether you’re evaluating elastomeric bearings, POT PTFE bearings, or spherical bearings, this article will help you decide what type of bearing to use for your specific application.

What are Rubber Bearings?

Rubber bearings are engineered components placed between structural elements—like bridge decks and piers—to facilitate controlled movement and absorb stress. These bridge support bearings accommodate rotation, horizontal displacement, and vertical loads caused by traffic, thermal changes, seismic activity, and settlement.

Manufactured using natural or synthetic elastomers like neoprene or reinforced rubber layers, they provide a combination of flexibility and strength. Rubber bearings reduce the transmission of vibrations to the superstructure and enhance the safety and lifespan of civil infrastructure.

In India, rubber bearings are manufactured under standards such as IS:3400, IRC:83, and RDSO guidelines, ensuring quality and suitability for projects like expressways, railway bridges, industrial platforms, and high-rise buildings. The difference between elastomeric and POT PTFE bearings lies in their structural makeup and load-bearing capabilities, which we explore below.

Types of Rubber Bearings

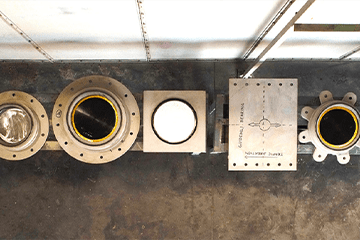

1. Elastomeric Bearings

Made from layers of natural rubber or neoprene, elastomeric bearings are the most widely used in small to mid-sized bridges and buildings. They allow for vertical load transfer and limited rotational and translational movement. Their low cost and low maintenance make them ideal for standard bridge and highway applications.

Compliant with IS:3400 and IRC:83, Ameenji Rubbers are also RDSO-approved for use in Indian Railways projects.

Use case: Highway overpasses, urban flyovers, and low seismic zones.

2. POT PTFE Bearings

These advanced bearings consist of a steel POT (container) with an elastomeric disc inside and a PTFE sliding surface on top. They support very high vertical loads while allowing for rotation and sliding. Known for high rotational stiffness and excellent performance in large-span bridges, POT PTFE bearings are ideal where space is limited and load requirements are extreme.

Use case: Long-span railway bridges, cable-stayed bridges, and flyovers in high seismic zones.

3. Spherical Bearings

Spherical bearings use a curved sliding interface and can accommodate large rotations and displacements. They are designed for heavy seismic zones and structures that experience large angular and linear movement.

Use case: Seismically active bridges, suspension bridges, and industrial facilities requiring multi-directional movement control.

Comparison Table

| Bearing Type | Load Capacity | Movement Allowed | Seismic Performance | Maintenance | Best For |

| Elastomeric | Low to Medium | Limited | Moderate (low zones) | Low | Flyovers, Small Bridges |

| POT PTFE | High | High (Sliding + Rot.) | High | Medium | Rail Bridges, Seismic Zones |

| Spherical | Very High | Very High | Very High | High | Suspension Bridges, Complex Loads |

This bridge bearing comparison helps clarify neoprene vs PTFE applications. For more specifications, refer to the Ameenji Rubber Bearings Catalog.

Use Cases by Industry

When selecting a rubber bearing type, the engineer must consider load, movement capacity, environmental exposure, and compliance with project codes.

Railways:

Indian Railways uses RDSO-approved POT PTFE bearings and elastomeric bearings in steel girder bridges, slab-on-beam structures, and overpasses. Rubber sole plates and rail pads further enhance shock absorption and track durability.

Highways & Bridges:

NHAI and PWD departments prefer neoprene elastomeric bearings for flyovers and road bridges due to their simplicity, cost-effectiveness, and compliance with IRC:83. Expansion joints and modular movement systems are often used in conjunction.

Seismic Zones:

For regions vulnerable to earthquakes, such as parts of North India or coastal zones, spherical bearings or POT PTFE bearings with enhanced displacement tolerance are installed for critical infrastructure.

Oil & Gas / Energy Sector:

In pipeline bridges and offshore platforms, custom PTFE bearings and load transfer pads offer thermal and vibrational stability under dynamic conditions.

Buildings & Industrial Platforms:

Large industrial facilities and malls incorporate elastomeric bearings in podium slabs or machinery platforms to manage stress concentration and movement.

These examples demonstrate the diversity of rubber bearing types across sectors. All products are engineered with durability, compliance, and performance in mind.

Buying Considerations

When choosing a rubber bearing, consider these key factors:

- Application Type: Is it a highway, railway, or seismic structure?

- Load Requirement: Determine vertical and horizontal load ranges.

- Movement Needs: Select based on expected displacement and rotation.

- Environment: Consider temperature, moisture, chemicals, or UV exposure.

- Certifications: Ensure compliance with RDSO, IS:3400, or CE Marking.

- Budget vs Performance: POT PTFE bearings offer more movement capacity but come at a higher cost.

📌 Tip: Always consult the bearing manufacturer’s technical sheet or a structural engineer to align with the project’s design requirements.

You can find technical details in the Ameenji Rubber Bearings Catalog, or contact our team for a tailored recommendation.

Conclusion

Understanding the different rubber bearing types is crucial for building safe, durable, and future-ready infrastructure. From elastomeric bearings for standard bridges to POT PTFE bearings for seismic and heavy-load structures, each solution plays a vital role. Whether you’re comparing neoprene vs PTFE, or selecting bearings for rail or highway, always prioritize certified quality and fit-for-purpose design.

✅ Ready to explore? Download the Ameenji Bearings Catalog, request a quote, or contact our technical team to find the best rubber bearing for your next project.

AUTHOR : Mr. Lakshmi Narayana

ROLE : Deputy General Manager

About The Author

Mr. Lakshminarayan has been with Ameenji for over 13 years. A rubber technologist, Mr. Lakshminarayan looks after all quality controls of the plant and looks after testing protocols and plans followed for inspection of railway and infrastructure components