Spherical Bridge Bearings for Complex Rotational Movements

Introduction

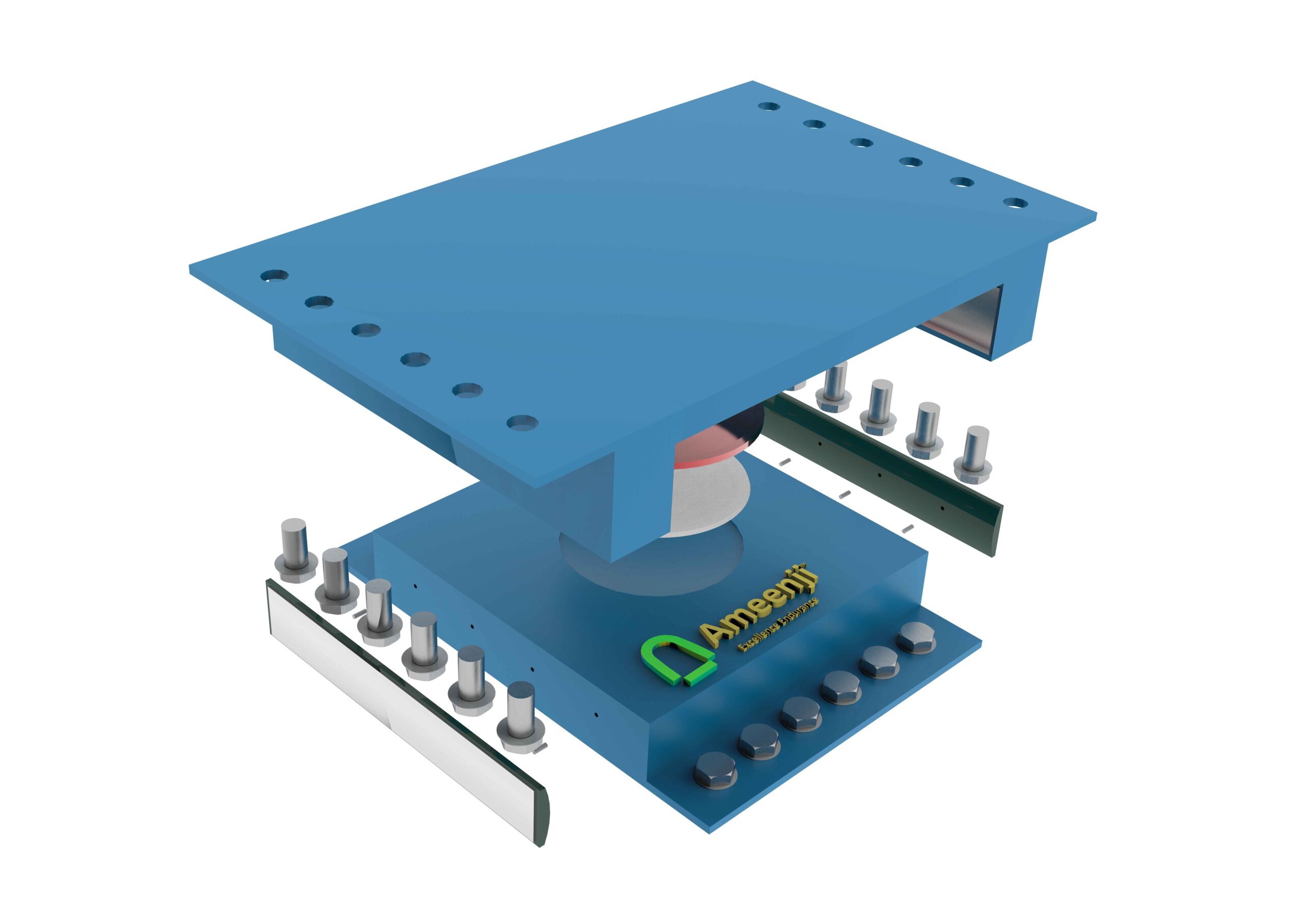

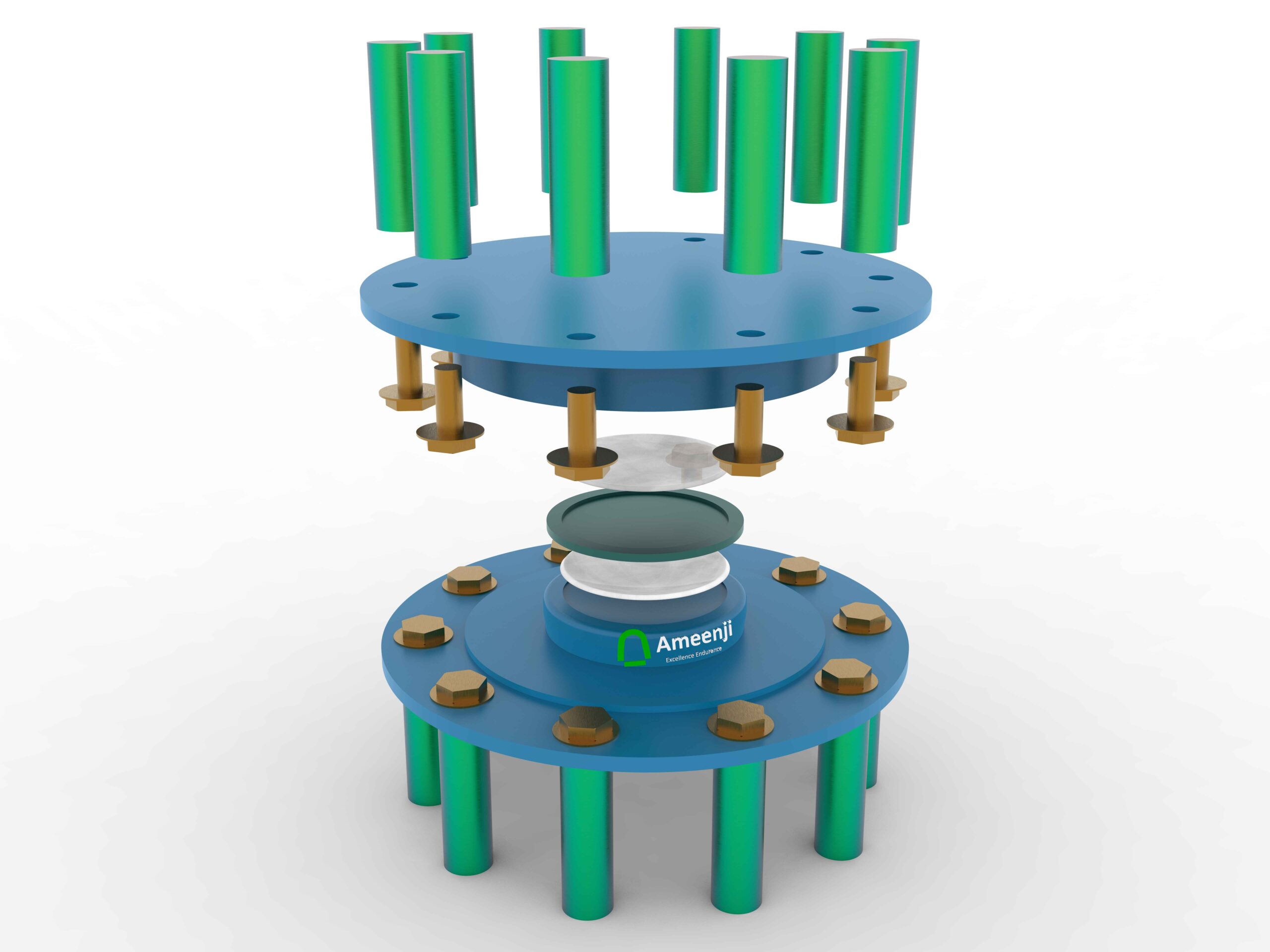

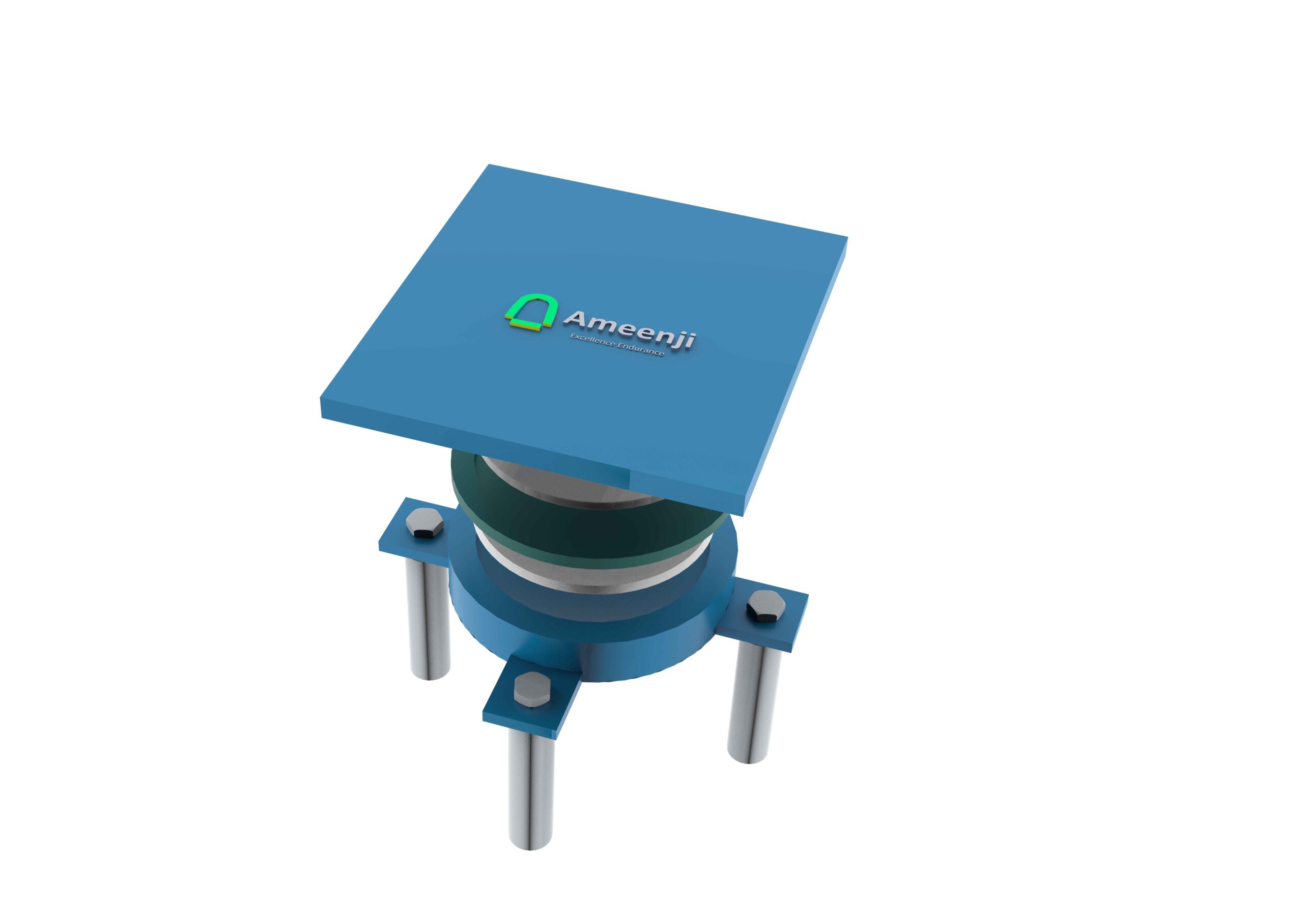

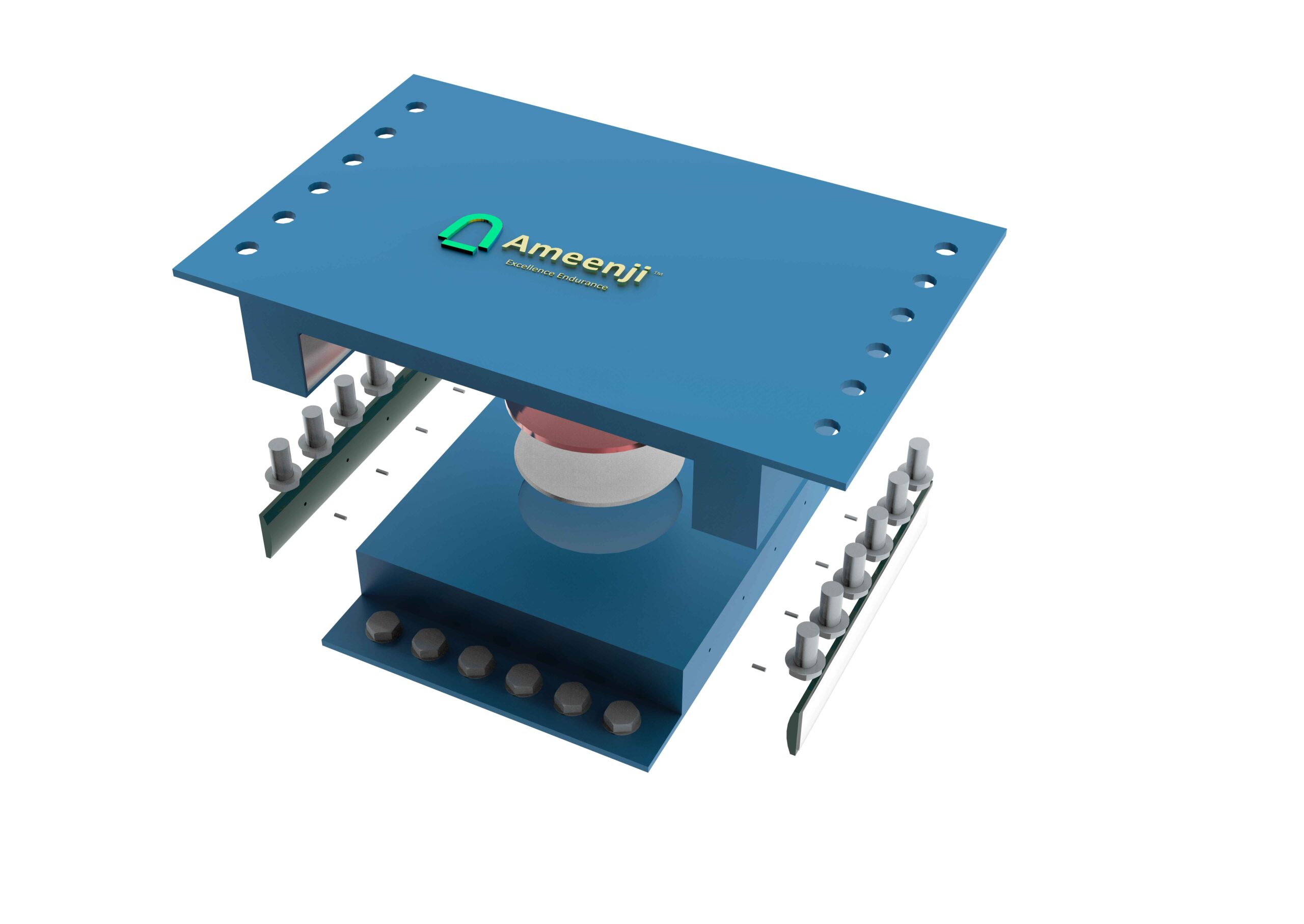

Spherical bearings, also known as spherical plain bearings, are a type of bearing designed to accommodate angular misalignment. They consist of an inner ring with a spherical convex outside surface and an outer ring with a correspondingly concave inside surface. This design allows the inner ring to rotate within the outer ring in multiple directions, making them ideal for applications where movement and alignment are crucial.

Key Features

-

- Spherical Surface : The core component of these bearings is a spherical surface, which allows for rotational movement in multiple directions. This helps accommodate angular misalignments between the bridge components.

- Load Transfer : Spherical bearings efficiently transfer vertical and horizontal loads from the bridge deck to the supports. This ensures the stability and safety of the structure under various conditions.

- Movement Accommodation : They allow for rotational movement, and some designs can also accommodate sliding movements. This flexibility is crucial in preventing damage to the bridge due to temperature changes, seismic activity, or traffic-induced vibrations.

- Material Composition : Spherical bearings are typically made from high-strength materials like stainless steel, combined with low-friction materials like PTFE (polytetrafluoroethylene) to reduce wear and allow smooth movement.

- Durability : These bearings are designed to withstand harsh environmental conditions, including temperature fluctuations, moisture, and chemical exposure, ensuring a long service life.

Applications

- Long-span bridges: Where large rotations and displacements are expected.

- Seismic zones : Where the bridge must accommodate movements during an earthquake.

- High-load structures: Where heavy loads need to be transferred safely to the supports.

Maintenance of Spherical Bearings

Regular maintenance of spherical bearings is essential to preserve their functionality and extend their lifespan. Routine inspections should focus on the bearing’s sliding surfaces, such as PTFE or stainless steel, to check for wear, dirt accumulation, or damage that might hinder movement. Corrosion protection is also key, especially in environments prone to moisture or salt exposure, as any rust or deterioration on the bearing’s metal components can compromise its performance. Proper lubrication is recommended where applicable to maintain low friction and smooth rotation.

By monitoring alignment, securing bolts, and keeping surfaces clean, regular maintenance can minimize potential damage and ensure the bearing’s optimal performance in supporting structural movements and loads.

Frequently Asked Questions

Spherical bridge bearings are preferred in high-load and high-rotation environments. They are especially effective in seismic zones and cable-stayed bridges.

Yes, our spherical bridge bearings are designed and tested as per MORTH and IRC:83 (Part II) standards, with full documentation and test reports.

Unlike Pot PTFE bridge bearings, spherical bearings allow rotation in all directions through a spherical calotte, making them suitable for complex bridge geometries.

We use high-strength forged steel, PTFE sliding surfaces, and stainless steel mating plates to ensure long-lasting and low-friction performance.

Yes, our spherical bridge bearings can be designed with seismic dampers and energy dissipation features as per project requirements.