Modular Bridge Expansion Joints for Large Span Bridges

Introduction

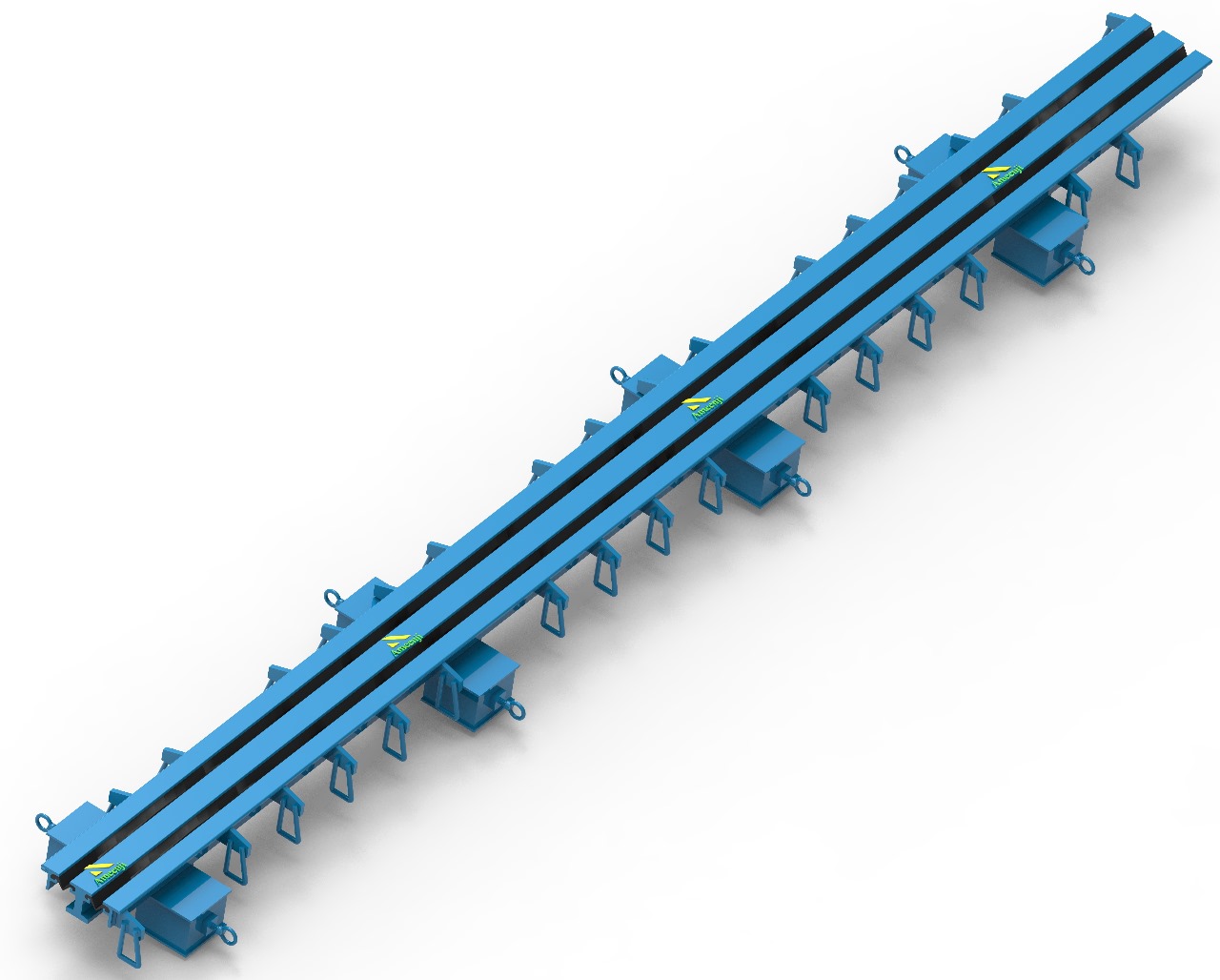

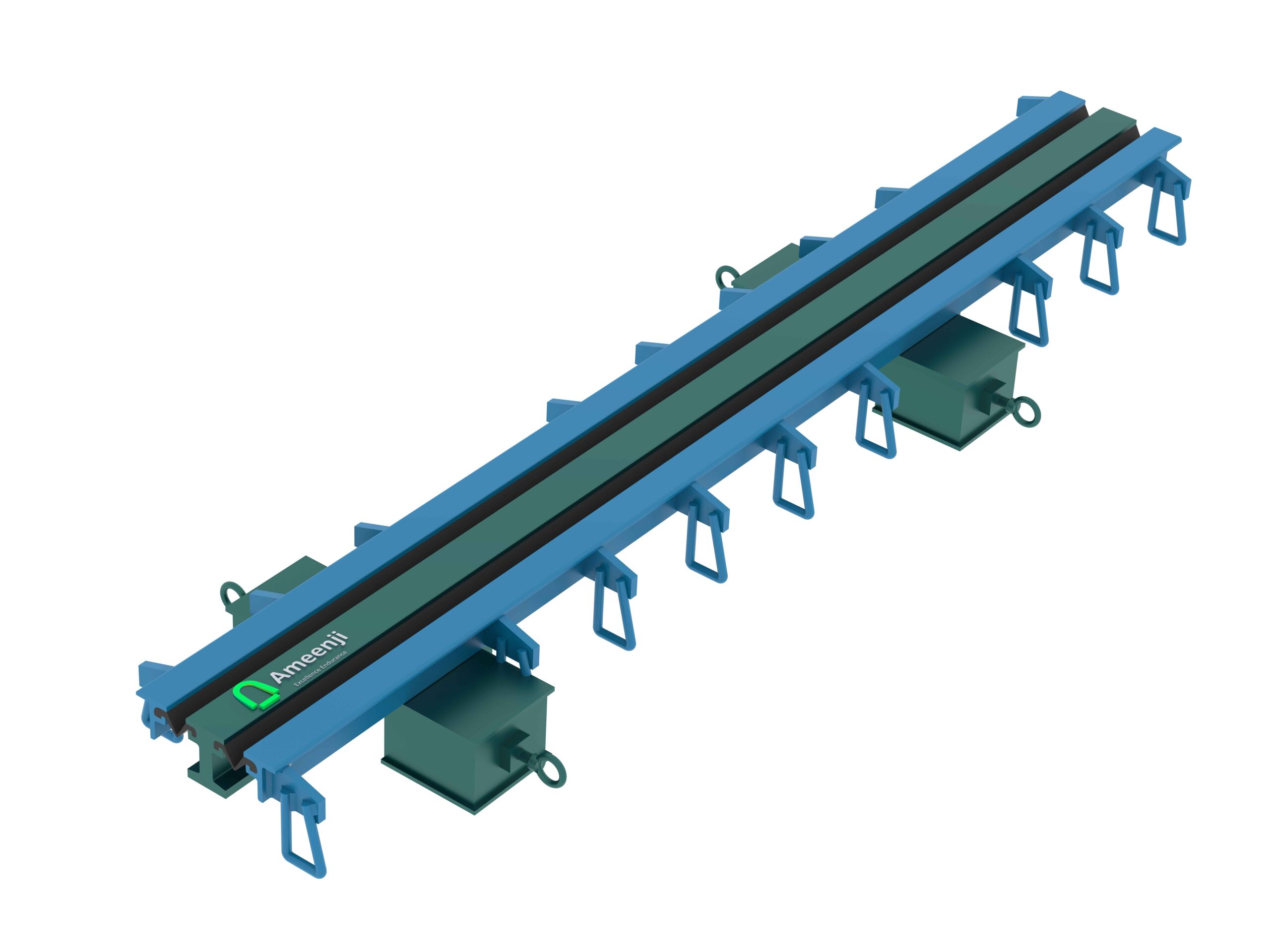

Modular Bridge Expansion Joints

“Innovative Modular Bridge Expansion Joints for Long-Lasting Infrastructure Solutions”

Modular Bridge expansion joints consist of a series of interconnected steel or elastomeric beams and seals, allowing for controlled movement in multiple directions. Unlike simple expansion joints, modular joints are constructed in segments to handle greater displacement while maintaining smooth surface continuity. This segmented design makes them ideal for structures that experience large or complex movement patterns.

Ameenji Rubber Limited is a leader in high-performance expansion joint solutions. With decades of expertise, we specialize in manufacturing Modular Bridge Expansion Joints that ensure durability, flexibility, and reliability. Our products are crafted from the finest materials and designed to meet the unique needs of today’s infrastructure demands. Whether for bridges, highways, or elevated structures, our Modular Bridge Expansion Joints provide essential protection against structural stress and environmental impact.

1. Exceptional Durability

Our Modular Bridge Expansion Joints are designed to withstand the toughest conditions, including heavy traffic loads, temperature fluctuations, and harsh weather. Built with high-grade materials and innovative design, Ameenji joints resist wear and tear, providing a long-lasting solution that minimizes maintenance costs.

2. Superior Flexibility for High-Movement Structures

Ameenji’s Modular Bridge Expansion Joints accommodate substantial movement in multiple directions, making them ideal for bridges, elevated roadways, and structures in seismic zones. The joints adjust to temperature changes, traffic shifts, and even seismic forces without compromising the structural integrity of the infrastructure.

3. Noise and Vibration Reduction

Traffic loads on bridges and elevated highways can generate significant noise and vibration, impacting driver comfort and the surrounding environment. Our Modular Bridge Expansion Joints are engineered to minimize noise and vibration, ensuring a smoother, quieter experience for vehicles and enhancing public satisfaction.

4. Customized Solutions

We understand that every project has unique requirements. Ameenji Rubber Limited offers tailored modular bridge expansion joint designs to match your project’s specific movement capacity, load tolerance, and environmental conditions. From single-seal to multi-seal configurations, we provide joint solutions that meet precise specifications.

5. Enhanced Safety and Performance

6. Low Maintenance Requirements

Built with durability and ease of use in mind, our Modular Bridge Expansion Joints are designed for minimal maintenance, with straightforward inspection and repair processes. When necessary, segments can be replaced individually, saving both time and money, and ensuring that your structure remains in top condition.

7. Environmental Sustainability

At Ameenji Rubber Limited, we are committed to sustainable practices. Our Modular Bridge Expansion Joints are manufactured with eco-friendly processes and materials that extend the life of infrastructure, reduce maintenance frequency, and lower the environmental footprint associated with repairs.

Applications

Ameenji Rubber Limited’s Modular Bridge Expansion Joints are trusted by engineers, builders, and infrastructure developers for a wide range of applications, including:

- Long-Span Bridges

- Elevated Highways and Roadways

- Seismically Active Regions

Each of these applications benefits from the reliability, durability, and high-performance capabilities of our Modular Bridge Expansion Joints, providing solutions that stand up to challenging demands.

Types of Modular Bridge Expansion Joints

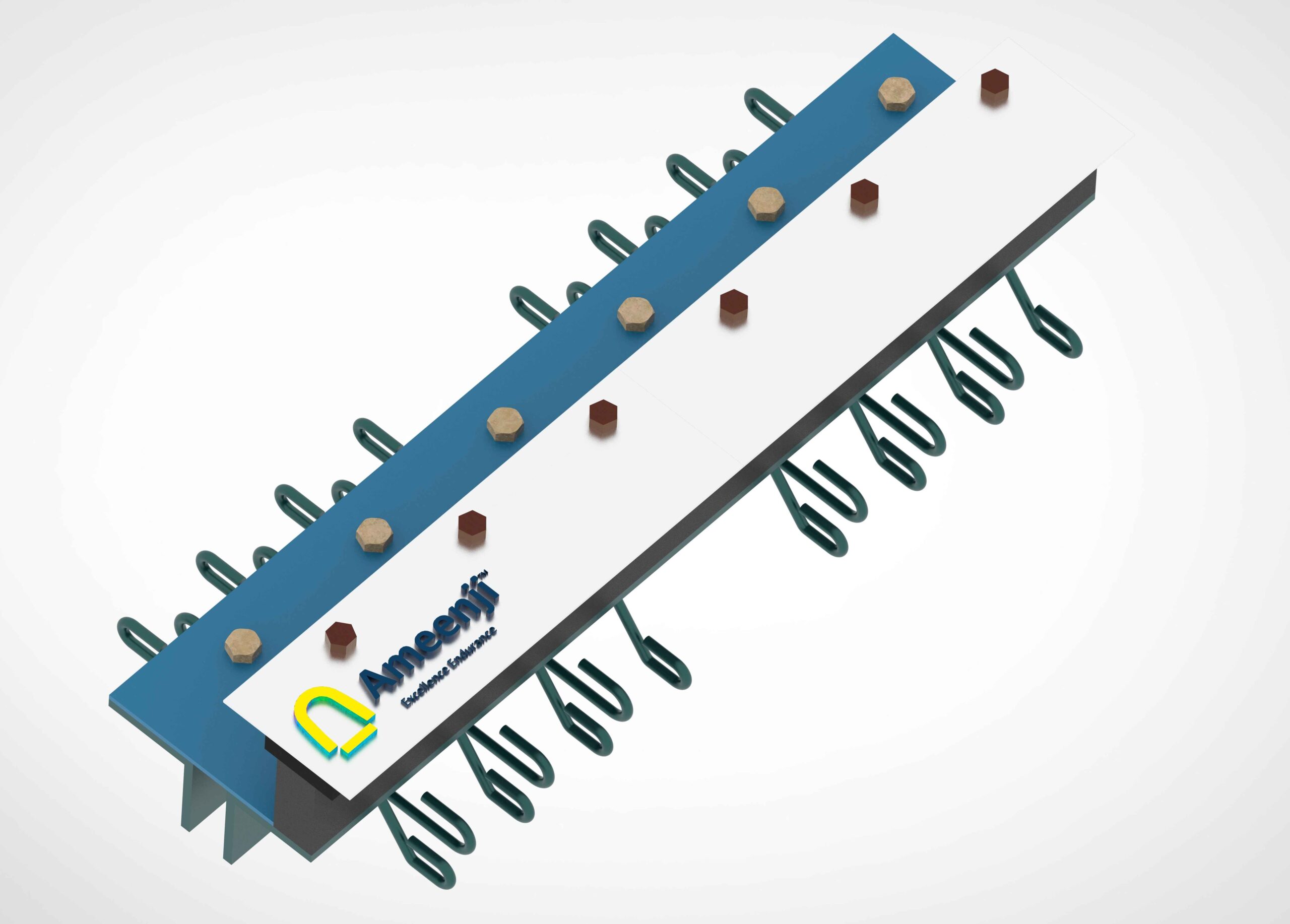

- Single-Seal: Suitable for moderate movements, these joints use a single elastomeric seal to manage expansion and contraction.

- Multi-Seal: Designed for large, high-movement structures, these joints feature multiple seals and beams to handle complex movement patterns and greater displacement.

- Sliding: In these joints, sliding plates enable movement along multiple axes, making them ideal for structures experiencing multi-directional forces.

How Modular Bridge Expansion Joints Work

Modular Bridge Expansion Joints are built with a combination of steel beams, elastomeric seals, and support bars to allow flexible movement. Each seal in the joint expands and contracts independently, enabling the joint to handle both small and large shifts in position. These joints also have built-in drainage systems to prevent water buildup, helping to protect the underlying structure and reduce the likelihood of corrosion.

Maintenance and Inspection

Modular Bridge Expansion Joints require regular inspection and maintenance to ensure optimal performance.

Key areas of focus include:

- Checking for Seal Integrity: Ensuring seals are intact and free of tears or damage from debris.

- Inspecting for Corrosion: Monitoring metal components for signs of corrosion, especially in high-moisture environments.

- Clearing Drainage Systems: Preventing water accumulation by maintaining clear drainage pathways.

- Verifying Movement Capacity: Checking that the joint is handling movement as designed without excessive wear on any component.

Routine maintenance and timely repairs are essential to maximizing the lifespan of Modular Bridge Expansion Joints and preventing costly structural issues.

With a legacy of excellence, Ameenji Rubber Limited offers cutting-edge Modular Bridge Expansion Joints backed by technical expertise, superior customer service, and a commitment to quality. We work closely with each client to ensure that our solutions meet and exceed their needs, delivering reliable, durable joints that keep infrastructure strong and resilient.

Frequently Asked Questions

Modular rubber expansion joints consist of multiple sealed units combined to accommodate large movements and rotations in bridges and highways, especially where traditional joints are insufficient.

With proper installation and maintenance, these joints can last over 15–20 years in demanding environments.